- Uses Pyrolysis, Gasification and Smoldering to Fully Decompose Organic Compounds to Zero Carbon

- Multiple Product Recovery Options

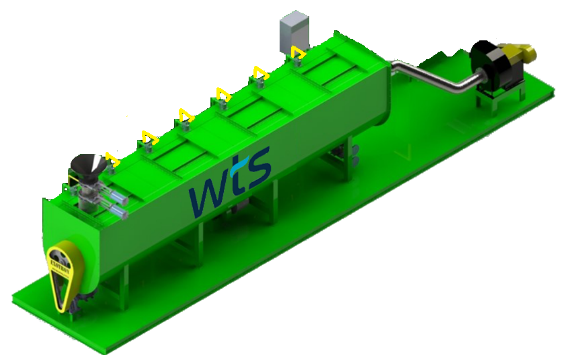

- Heavy-Duty Systems Eliminate Rheology Concerns Allowing Maximum Product Recovery

- Carefully controlled process parameters provides the ability to Exercise Control Over Available Reaction Pathways

- No Direct Flame Impingement

- Subpart X Permit, USEPA RCRA Waste

- Multiple Temperature Zones

- Oxygen Control Prevents Nitrogen in feed from forming NOx

- 2NO + CO à N2O + CO2 (or)

- N2O + CO à N2 + CO2 (etc.)

Sample Product Recovery and Material Management Applications

- Product Left in Waste Streams for Viscosity Improvements

- Valuable Metals from Liquids, Sludges or Solids

- Petroleum Processes: Exempted Oil Recovery from OBHSM

- On-Site Catalyst Processing for Metals Recovery

- Manage Difficult Process Wastes On-Site Cost Effectively

- Reactive or Energetic Materials

- Viscous, Sticky, Gummy or other Problematic Material

- Material Generated at Elevated Temperatures or that Solidify on Cooling

- Contaminated Soil or other Media

- Highly Halogenated or Other Corrosive Material