Overview – Source American Trucking Association 10/25/2021

In 2021 a historic shortage of just over 80,000 drivers (current number of drivers vs. the optimal number of drivers based on freight demand) was reached. This is most acute in the longer-haul, for hire truck market.

No Single Cause:

- High average age of current drivers, leads to a high number of retirements;

- Women making up only 7% of all drivers, well below their % of total workforce;

- The federally mandated minimum age of 21 to drive commercially across state lines poses a significant challenge to recruiting new drivers;

- The pandemic caused some drivers to leave the industry, plus truck driver training schools trained far fewer drivers than normal in 2020;

- Lifestyle issues, notably time away from home, especially in the longer-haul market;

- Infrastructure and other issues, for example, a lack of truck parking spots, which causes drivers to stop, driving earlier than they need to so they can get a spot for the night, and congestion which limits drivers’ ability to safely and efficiently make deliveries.

Impact

The transportation of Waste and By-products requires specialized permits, handling and equipment. As driver shortages expand, the impact is felt greatest in the waste and by-product management industry.

Many large quantity generators have exceeded their 90-day compliance requirements for storing hazardous waste on-site due to the driver shortages, last minute cancellations and inability to obtain slots at end disposal facilities.

Why is this a long-term impact?

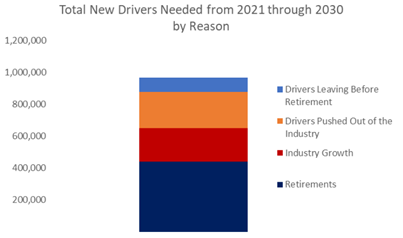

The transportation industry will need to recruit 1,000,000 new drivers in the next decade.

How is WTS and our Stakeholders Adapting?

- Pre-scheduling as far out as feasible. Proactively securing the truck and “building out the load”

- Utilizing data analytics and historical generation data and facility production forecasting to plan future shipments.

- Maximize each load across generator sites/locations in a region.

- Build out inventory data using handheld, bar coding technology and LMWTS inventory modules.

- Utilize hubs for efficiency and to also maximize loads.

- Evaluate opportunities for dedicated transportation service.

- Establish multiple backups for transportation of assets.

- Determine if alternative transportation modes are possible: rail, barge, vessel, over the sea.

- Reduce waste generation through sustainable materials management and systematic by-product management planning.

- Where possible and compatible, bulk up materials to maximize volumes and optimize loads.

- Identify, evaluate and implement delivery of materials to sites that are more proximate to the generating site.

- Evaluate all streams for direct re-use and alternative management potential including recycling, recovery, beneficial re-use or fuel substitution and energy from waste solutions.

- Review each stream and update waste profile descriptions where appropriate

- Is the material generated in a state that has adopted the 2018 New Definition of Solid Waste (2018 NDSW) If yes, can the material be viably reclaimed?

We are grateful to each of our stakeholders as we adapt and seize new opportunities to continue our beyond compliance performance, provide exceptional service, deliver operational efficiencies and enhance the sustainability of our stakeholders. Please reach out to your WTS representative with any questions or thoughts on ways we can further adapt together.